Easy to Operate High Efficiency Filling Machines for Foaming Chemical Solution in Pail_

Easy-to-Operate, High-Efficiency Pail Filling Machine for Foaming Chemical Solutions

Overview:

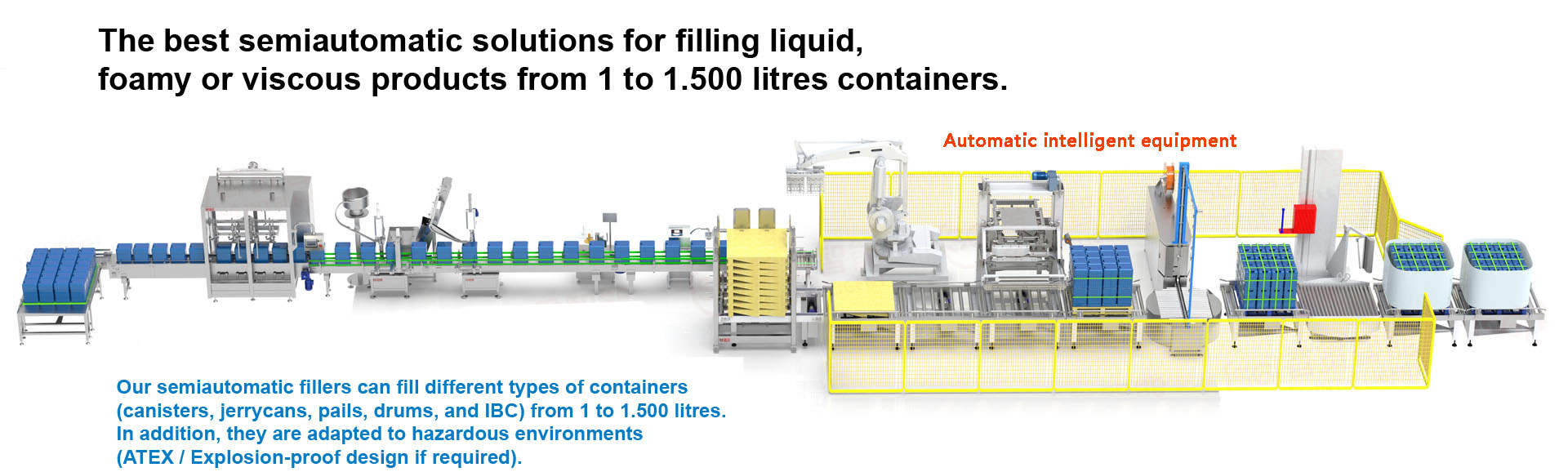

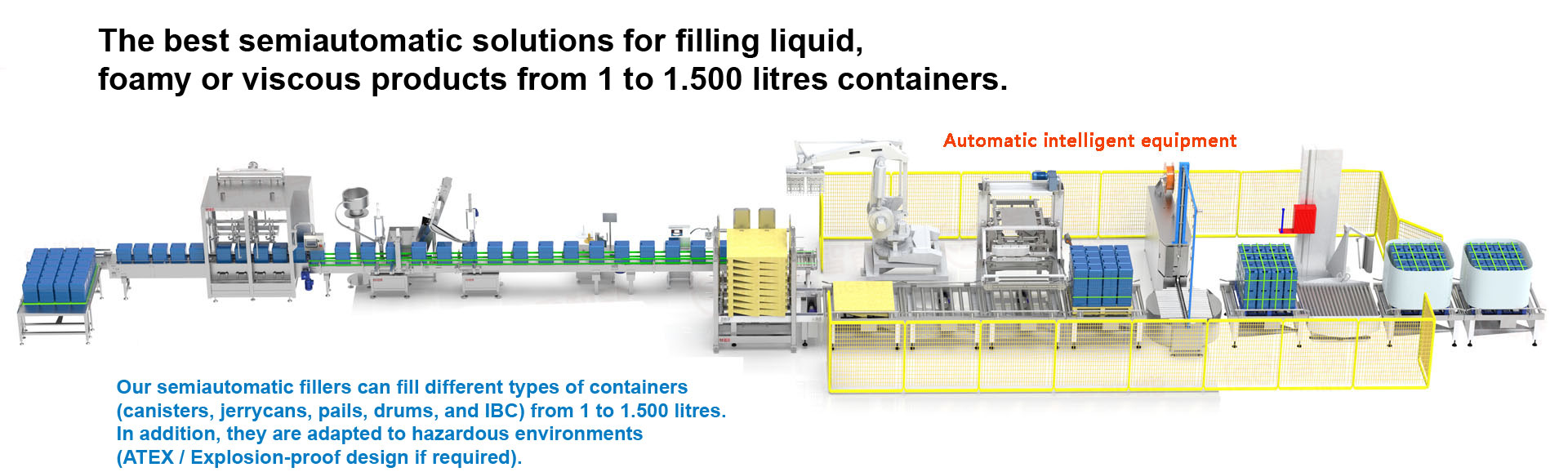

The Semi-Automatic Pail Filling Machine is designed for precise, splash-free filling of foaming chemical solutions into 5–25L pails. It combines user-friendly operation, anti-foam technology, and high-efficiency features to ensure safety, accuracy, and productivity.

Key Features:

Foam Management:

Anti-Foam Nozzle: Dual-layer design with a foam-breaking inner chamber and drip-free outer ring.

Low-Shear Filling: Minimizes turbulence to reduce foam generation during dosing.

Vacuum Breaker (Optional): Prevents airlocks caused by foam in the pump or pipeline.

Ease of Operation:

Touchscreen HMI: Intuitive interface for preset recipes, volume adjustment, and diagnostics.

Foot Pedal Start: Hands-free activation for manual pail placement.

Quick Changeover: Tool-free nozzle swaps for different pail sizes (e.g., 5L, 10L, 20L).

High Efficiency:

Weight-Based Accuracy: ±0.1% filling precision using load cells and automatic stop.

High-Flow Pump: Capable of filling 20L pails in under 30 seconds (adjustable speed).

Continuous Duty: Designed for all-day operation with minimal downtime.

Safety & Compliance:

ATEX/IECEx Certified: Safe for flammable or hazardous chemical environments.

Static Dissipation: Conductive materials and grounding systems to prevent sparks.

Corrosion-Resistant Build: 304/316L stainless steel frame, PTFE seals, and chemical-resistant coatings.

Cleaning & Maintenance:

CIP Compatibility: Automated clean-in-place cycles with solvent or water.

Removable Drip Tray: Stainless steel tray for easy cleanup of spills or residue.

Nozzle Purging: Automatic blowdown with air or solvent to prevent clogging.

Customization Options:

Nitrogen Blanketing (Optional): Inert gas purge to suppress foam and protect chemicals.

Fumes Extraction: Integration with overhead arms or downdraft tables.

Barcode Scanning: Track batches and ensure traceability.

Technical Specifications:

Filling Range: 1–25 liters (adjustable in 0.1L increments).

Accuracy: ±0.1% of target weight.

Materials: 304/316L stainless steel, PTFE seals, FKM gaskets.

Safety Certification: ATEX, IECEx, CE.

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Environment Rating: IP65 (dust and water resistant).

Operation Steps:

Pail Placement: Manually position the empty pail under the filling nozzle.

Start Cycle: Initiate via foot pedal or HMI touchscreen.

Foam-Controlled Filling: The machine fills the pail while minimizing foam through low-shear flow and anti-foam nozzle technology.

Nitrogen Purge (If Equipped): Optional inert gas blanketing to suppress residual foam.

Pail Removal: Manually remove the filled pail or use an optional conveyor.

Cleanup: Nozzle purges automatically to prevent clogging.

Applications:

Foaming Chemicals: Surfactants, detergents, soaps, and specialty cleaners.

Industrial Solutions: Coatings, adhesives, and polymers prone to foaming.

Pharmaceuticals & Cosmetics: Foam-sensitive liquid formulations.

Benefits:

Foam Reduction: Advanced nozzle and low-shear technology minimize foam during filling.

User-Friendly: Touchscreen controls, foot pedal start, and quick changeovers simplify operation.

High Throughput: Fast filling cycles and continuous duty maximize productivity.

Safety: ATEX/IECEx compliance and static dissipation for hazardous environments.

Customization: Tailored for specific pail sizes, chemical types, and foam management needs.

Low Maintenance: Robust design with CIP and removable components for easy cleaning.

Why Choose Us?

As a manufacturer, we specialize in custom filling solutions for foaming chemicals, coatings, and industrial liquids. Our machines are built to balance ease of use, safety, and efficiency while addressing challenges like foam control. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://m.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic Edible Oil/Olive Oil/Drinking Water/Plastic Drum Liquid Filling Machine[2025-05-29]

-

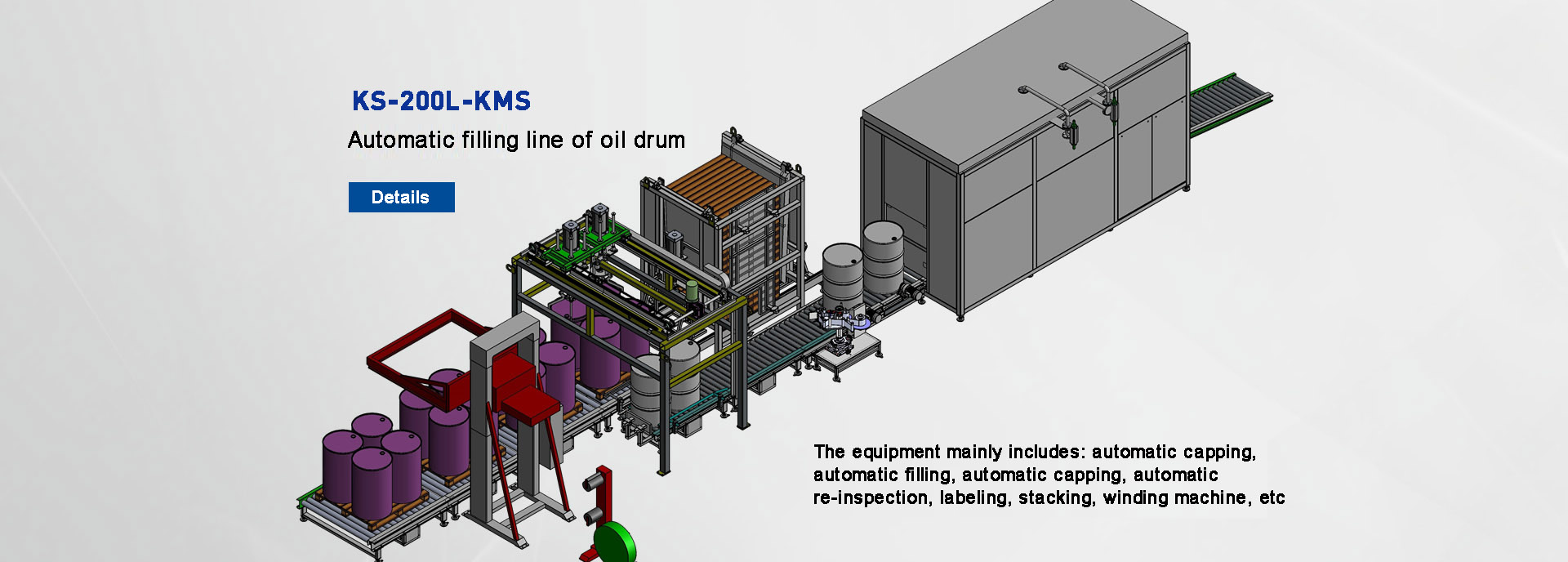

Multifunctional Filling Machine Is Suitable for Filling 200L Slurry/Emulsifiable Concentrate/Resin Drum[2025-05-13]

-

Semi-Automatic Industrial Raw Juice Paste Concentrate Drum Filling Machine[2025-06-05]

-

Gravity Epoxy Resin IBC Filling Machine for 1000L[2025-05-07]