High-Capacity 200L Drum Filling Machine for Industrial Liquid Packaging

High-Capacity 200L Drum Filling Machine for Industrial Liquid Packaging

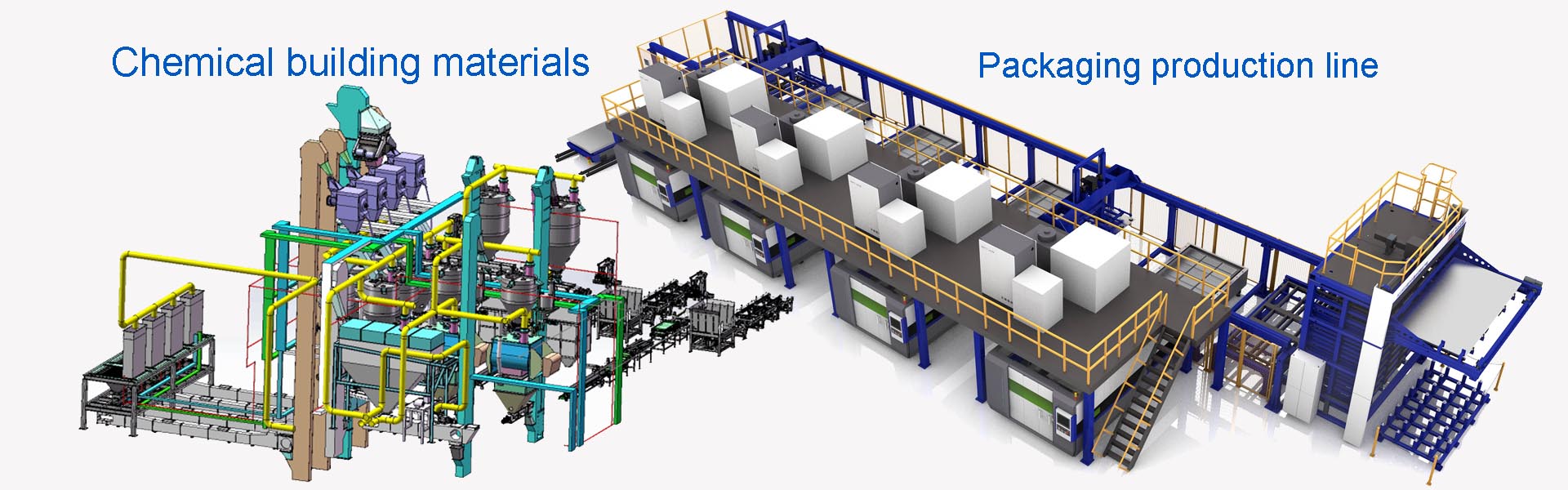

Overview:

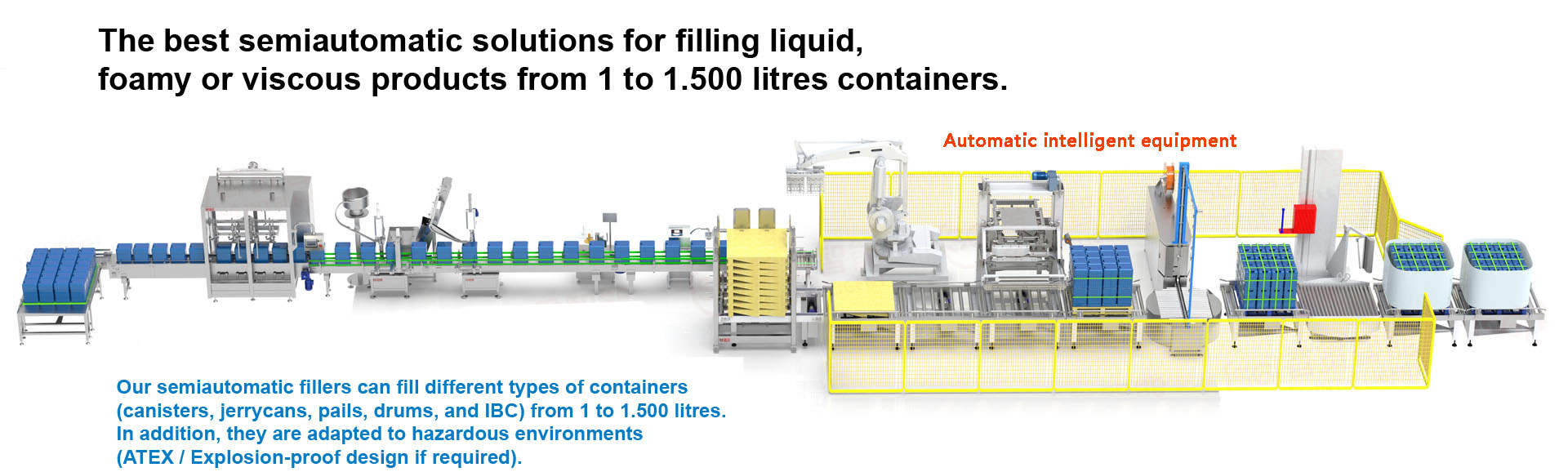

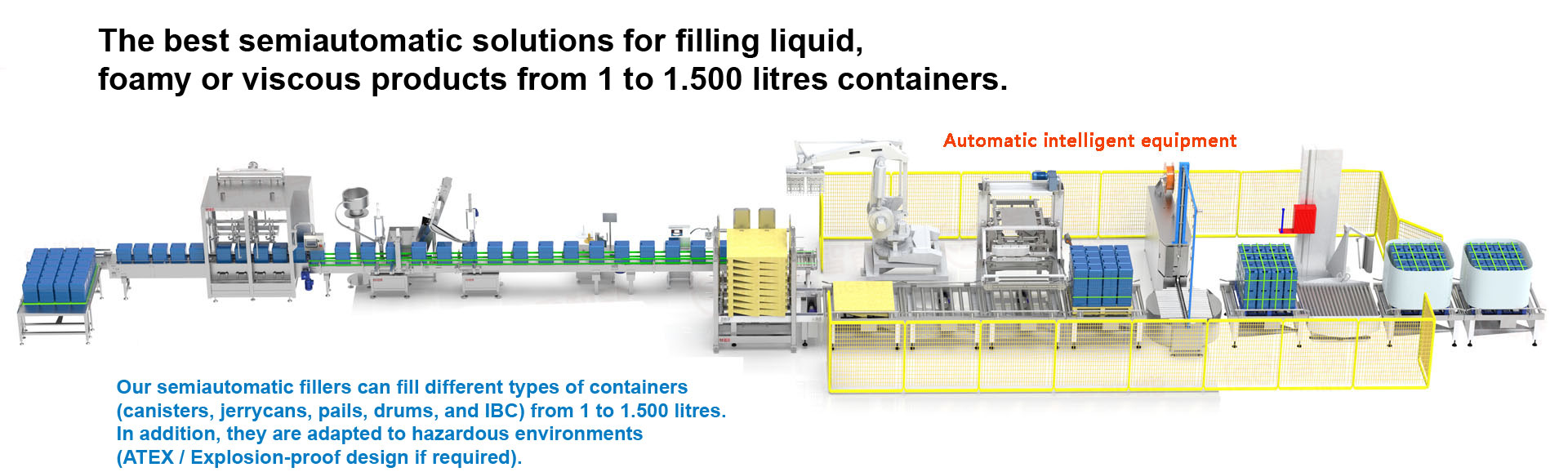

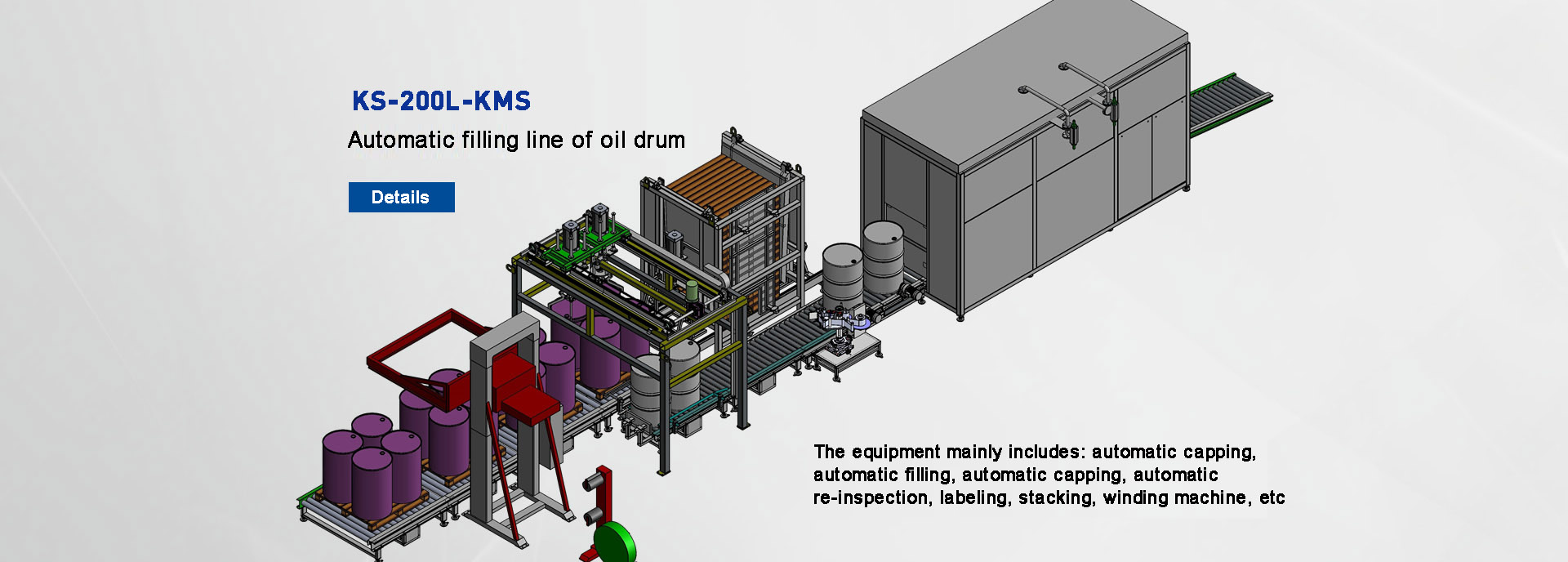

The High-Capacity 200L Drum Filling Machine is designed for efficient, precise, and safe filling of industrial liquids into 200-liter drums. Ideal for chemicals, lubricants, adhesives, oils, and hazardous materials, this machine combines accuracy, speed, and safety features to meet the demands of high-volume packaging operations.

Key Features:

1. Precision Filling:

Accuracy: ±0.5% filling accuracy, ensuring consistent product levels and minimizing overfill/underfill.

Flow Control: Adjustable flow rates (1–100 L/min) with mass flow meters or load cells for drip-free filling.

Automatic Calibration: Self-checking system compensates for temperature, viscosity, and container variations.

2. High-Capacity Handling:

Container Compatibility: Suitable for 200L drums, IBCs (1,000L), and intermediate bulk containers (IBCs).

Speed: Capable of filling up to 10 drums per hour (depending on product viscosity and setup).

3. Safety & Compliance:

ATEX/IECEx Certification: Safe for use in explosive atmospheres (Zone 1/2).

Static Dissipation: Grounding systems and anti-static nozzles prevent sparks during filling.

Spill Prevention: Drip-free nozzles, spill trays, and emergency stop buttons.

Fume Management: Optional vapor extraction arms to capture volatile fumes.

4. Automation & Control:

Touchscreen HMI: User-friendly interface for recipe storage, batch counting, and real-time monitoring.

PLC Integration: Compatible with SCADA systems for seamless workflow automation.

Remote Access: IoT-enabled diagnostics and troubleshooting (optional).

5. Customization Options:

Materials: 316L stainless steel, PTFE, or Hastelloy for corrosion resistance against aggressive chemicals.

Nozzle Types: Standard splash-proof, funnel-style, or custom configurations (e.g., nitrogen blanketing).

Conveyor Systems: Integrated roller or belt conveyors for automated drum handling.

6. Environmental Protection:

Inert Gas Purge: Nitrogen or CO? blanketing to prevent oxidation or contamination.

Drum Sealing: Optional automatic capping/sealing modules for tamper-evident closures.

Technical Specifications:

Filling Capacity: 200L drums (adjustable for smaller/larger containers).

Accuracy: ±0.5% by mass or volume.

Flow Rate: 1–100 L/min (configurable).

Power Requirements: [Insert Voltage] (e.g., 220V/50Hz or 480V/60Hz).

Dimensions: Customizable based on integration needs (e.g., footprint, height).

Safety Compliance: ATEX, IECEx, ISO 9001, CE.

Applications:

Chemicals: Acids, bases, solvents, and specialty formulations.

Oils & Lubricants: Engine oils, greases, and industrial lubricants.

Food & Beverage: Edible oils, syrups, and food-grade additives.

Pharmaceuticals: APIs, excipients, and liquid medications.

Petrochemicals: Fuels, biodiesel, and petrochemical blends.

Benefits:

Efficiency: High-speed filling with minimal downtime reduces labor costs and increases throughput.

Safety: Explosion-proof design, static control, and spill prevention protect operators and the environment.

Precision: Accurate filling minimizes product waste and ensures regulatory compliance.

Flexibility: Customizable for diverse chemistries, container sizes, and automation levels.

Scalability: Suitable for small-scale production or large industrial operations.

Optional Accessories:

Conveyor Systems: Roller or belt conveyors for automated drum loading/unloading.

Labeling Machines: Barcode/batch number printers for traceability.

Weighing Scales: Inline verification of filled weights.

Vapor Extraction Arms: Fume capture for volatile substances.

Nitrogen Purge Systems: Inert gas blanketing to preserve product integrity.

Why Choose This Machine?

The High-Capacity 200L Drum Filling Machine delivers reliable, high-precision filling for industrial liquids while prioritizing safety, efficiency, and compliance. Its robust construction, advanced automation, and customizable features make it ideal for industries where accuracy, worker safety, and environmental protection are critical. Perfect for chemical manufacturers, oil refineries, food processors, and pharmaceutical companies.

Immediate Order:

Website: http://m.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic Mouth-Finding Coating Cans Filling Machine for 5-25L[2025-05-07]

-

200L Drinking Mineral Water Bottling Filling Machine[2025-04-15]

-

Automatic High-Speed Single-Head Lubricating Oil/Engine Oilliquid Filling Machine 1-25L[2025-05-17]

-

Automatic 55 Gallon 200L Steel Drum Bottom up Filling Machine[2025-04-15]