Intelligent Flavor and Fragrance Filling Equipment

Intelligent Flavor and Fragrance Filling Equipment

Overview

The Intelligent Flavor and Fragrance Filling Machine is a cutting-edge solution designed for precise, contamination-free filling of liquid flavorings, fragrances, essences, and aromatic oils. Equipped with advanced automation, IoT connectivity, and adaptive technology, it ensures optimal accuracy, product integrity, and efficiency in industries such as food & beverage, cosmetics, perfumery, and pharmaceuticals.

Key Features

Precision & Accuracy

Micro-Volume Filling: Adjustable fill volumes from 0.5mL to 5L with ±0.2% accuracy, ideal for small vials or bulk containers.

Weight-Based Calibration: Integrated load cells for gravity-fed or pressurized filling, ensuring consistency in viscous or low-viscosity products.

No-Drip Technology: Seal-off valves and drip-free nozzles prevent product wastage and cross-contamination.

Intelligent Automation

AI-Powered Recipe Management: Stores and recalls custom recipes for different SKUs, including fill volumes, speeds, and container types.

Self-Learning Calibration: Automatically adjusts fill parameters based on real-time viscosity, temperature, and pressure data.

Vision Systems: Cameras verify fill levels, cap placement, and label alignment for error-proof operations.

Product Protection

Inert Gas Blanketing: Nitrogen or argon purging preserves delicate flavors and fragrances by preventing oxidation.

Vacuum Filling Option: Eliminates air bubbles and minimizes exposure to oxygen for light-sensitive or volatile products.

Stainless Steel Enclosure: 316L stainless steel contact parts with optional electropolishing or PTFE coatings for corrosion resistance.

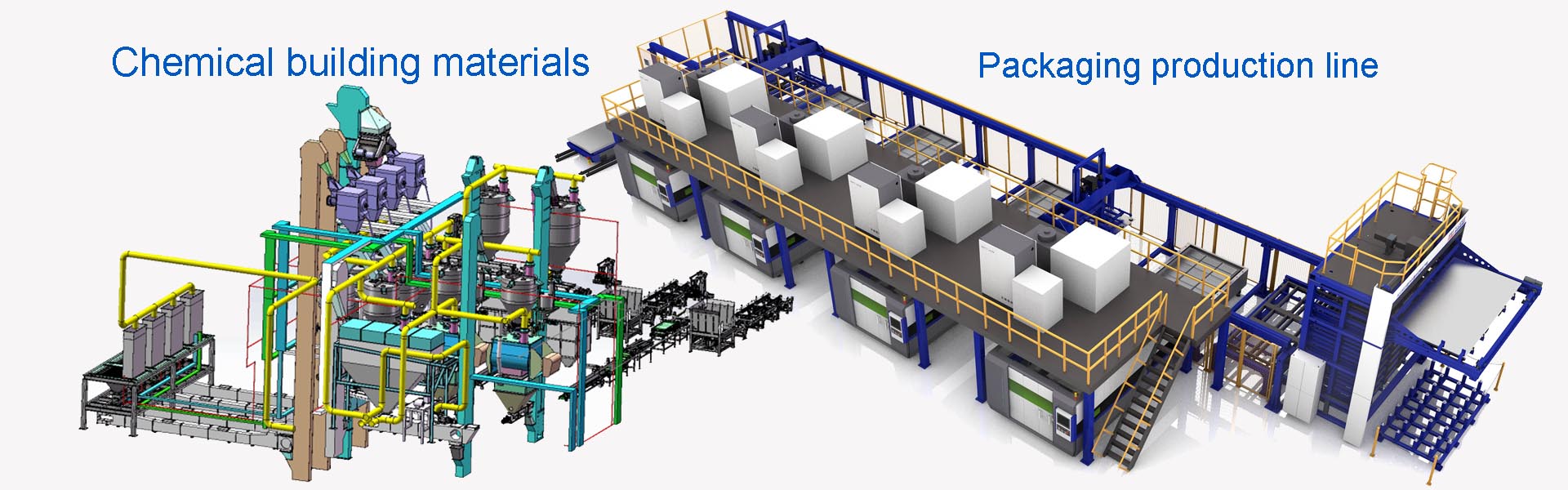

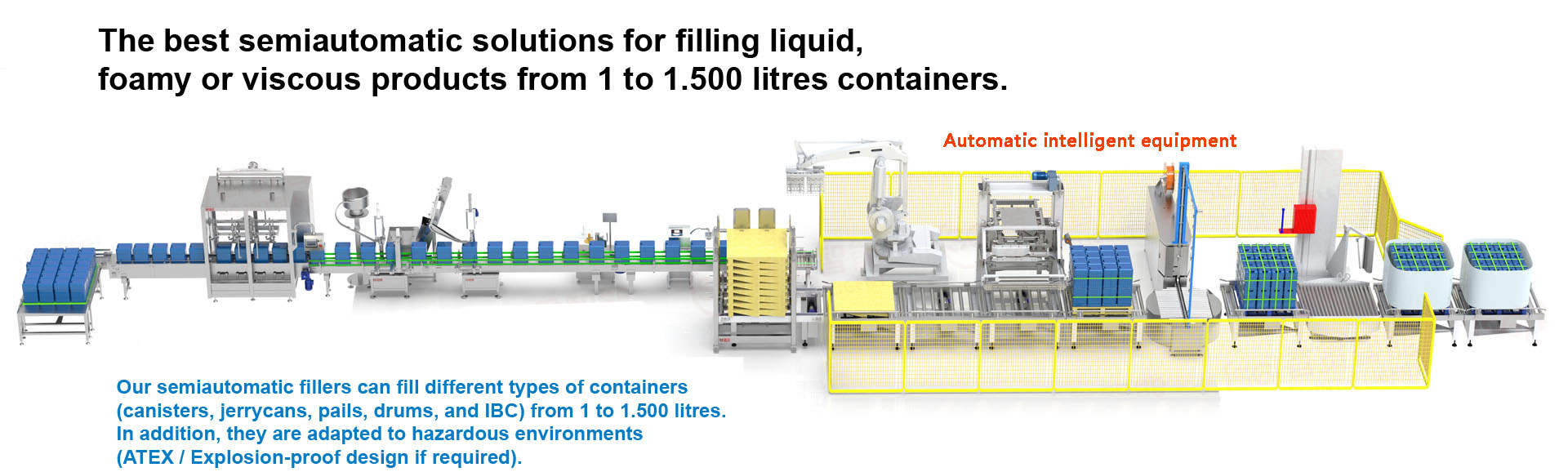

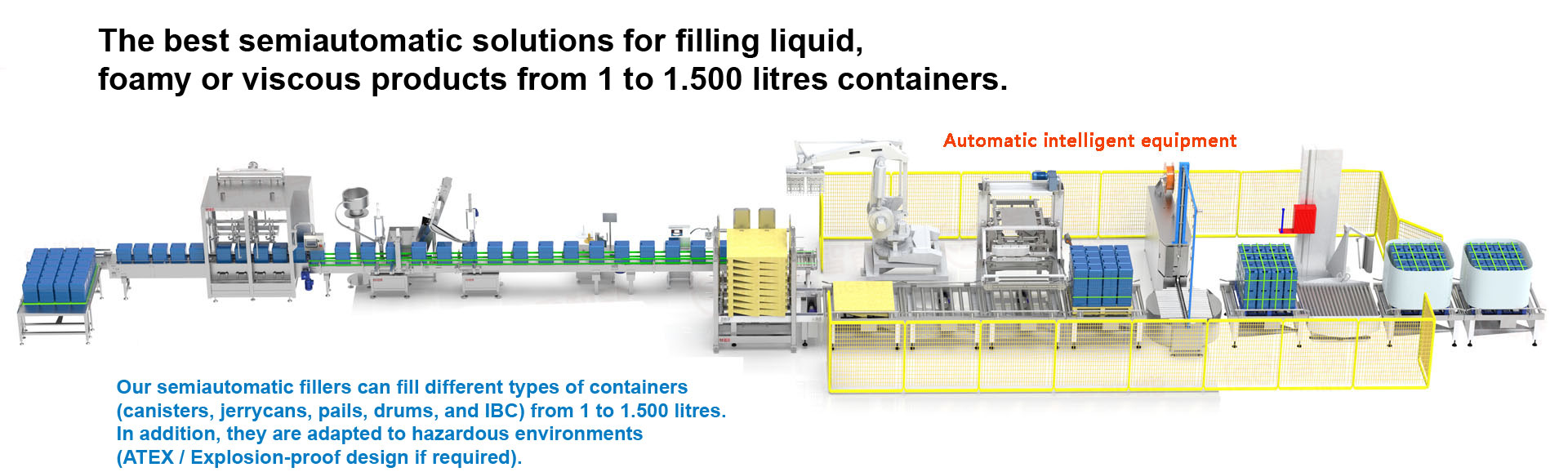

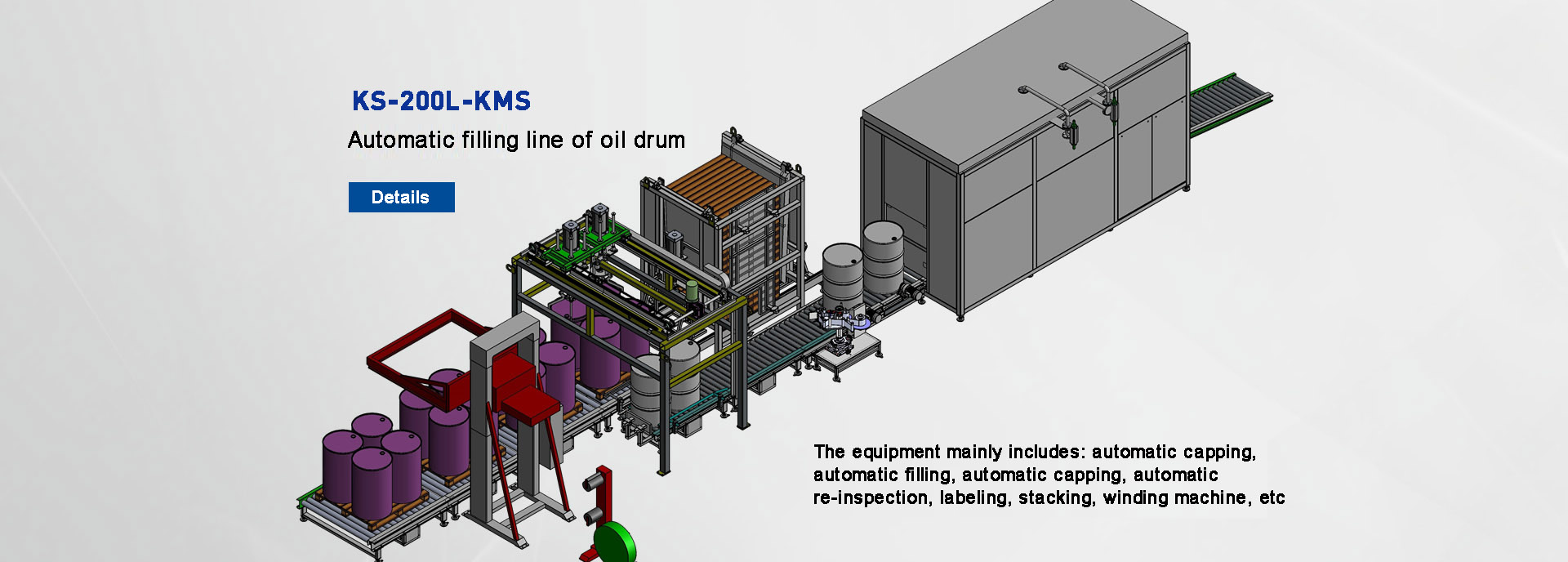

Flexibility & Versatility

Modular Design: Easily interchangeable nozzles, pumps, and capping systems for bottles, jars, vials, or drums.

Multi-Product Handling: Quick-changeover kits for switching between flavors, fragrances, or oils without cross-contamination.

Temperature Control: Heated or cooled hoppers/pipes to maintain product stability (e.g., melting solid fragrances or chilling volatile oils).

Connectivity & Data Integration

IoT-Enabled: Real-time remote monitoring, diagnostics, and OEE reporting via cloud connectivity.

MES/ERP Compatibility: Seamless integration with enterprise systems for batch tracking, inventory management, and traceability.

Predictive Maintenance: AI analyzes usage patterns to alert operators to potential issues before failure occurs.

Applications

Food & Beverage: Essential oil filling, flavor concentrates, extracts, and aromatic syrups.

Cosmetics & Perfumery: Fragrance oils, essential oils, parfums, and aromatherapy blends.

Pharmaceuticals: Scented medications, flavored syrups, and aromatherapeutic formulations.

Chemicals: Specialty solvents, aroma chemicals, and fine chemicals.

Optional Enhancements

Capping & Sealing: Explosion-proof crimpers, sprayers, or tamper-evident caps.

Labeling Systems: Integrated applicators for front/back labels, barcodes, or QR codes.

Nitrogen Purge: Inline gas injection to maintain product freshness during filling.

Atmosphere Control: Glove boxes or laminar flow hoods for oxygen-sensitive products.

Technical Specifications

Filling Range: 0.5mL–5L (adjustable)

Accuracy: ±0.2% (volumetric) / ±0.1% (weight-based)

Speed: Up to 1,500 containers/hour (dependent on container size)

Materials: 316L stainless steel (optional PTFE, Hastelloy, or electropolished finishes)

Automation: Touchscreen HMI, PLC control, and AI-driven recipe management

Connectivity: Ethernet, Wi-Fi, OPC UA, MQTT, and cloud-ready APIs

Benefits

Unmatched Precision: Micro-volume accuracy and self-calibrating technology ensure consistent fills.

Product Integrity: Inert gas blanketing, vacuum filling, and contamination controls preserve aroma and flavor.

Flexibility: Modular design and quick changeover capabilities handle diverse product portfolios.

Data-Driven Efficiency: IoT connectivity and AI analytics optimize productivity and reduce downtime.

Compliance: Full traceability, batch logging, and GMP/HACCP-ready documentation.

Why Choose This Equipment?

This intelligent filling solution combines precision engineering, adaptive automation, and product protection to meet the unique demands of flavor and fragrance manufacturing. Perfect for high-value, sensitive products requiring contamination-free, accurate, and efficient filling.

Ready to elevate your flavor and fragrance production? Contact us for a tailored demonstration and consultation!

Website: http://m.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com