Weighing Explosion-proof Filling Machine for Coating Lubricant/white Latex

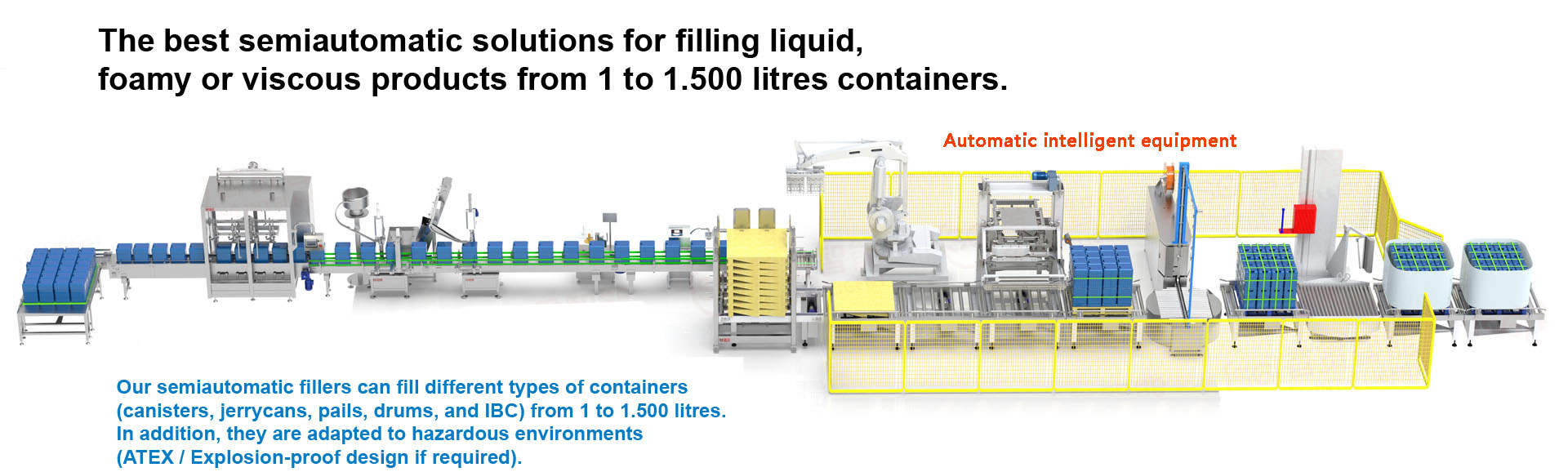

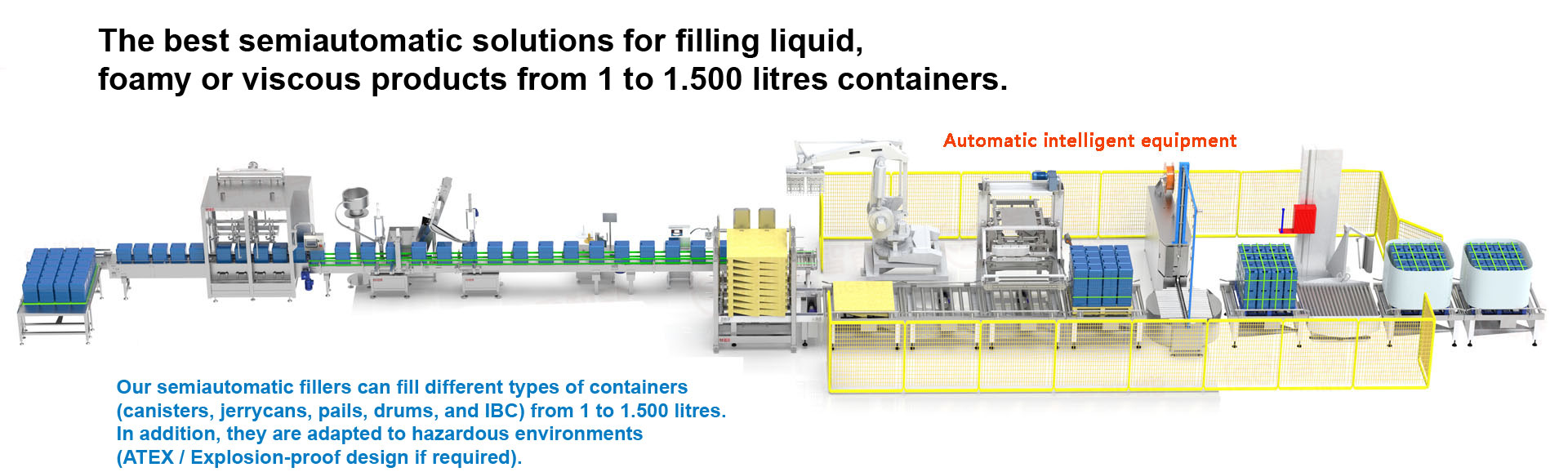

The Weighing Explosion-Proof Filling Machine for Coating Lubricant/White Latex is a specialized, high-precision system designed to handle flammable or hazardous liquids in explosion-prone environments. Below is a detailed overview of its features, applications, benefits, and technical specifications tailored to coating lubricants and white latex.

Key Features:

Explosion-Proof Design:

ATEX/IECEx Certified: Compliant with international safety standards for hazardous environments (Zone 1/21 or Zone 2/22).

Stainless Steel Construction: Made from 304/316L stainless steel for corrosion resistance and compatibility with aggressive chemicals like white latex and coating lubricants.

Static-Dissipative Materials: Prevents sparks and ensures safe operation in explosive atmospheres.

Weighing System:

High-Precision Load Cells: Ensures ±0.5% accuracy in filling volumes.

Weight-Based Filling: Eliminates overfilling or underfilling by measuring the exact weight of the liquid dispensed.

Tare Weight Function: Accounts for container weight for precise net filling.

Touch Screen HMI (Human-Machine Interface):

Intuitive touch screen for easy programming, monitoring, and adjustment of filling parameters.

Stores multiple product profiles for different liquids and container sizes.

Displays real-time data (e.g., fill volume, speed, error codes).

Intelligent Filling Technology:

Drip-Free Nozzles: Prevents spillage and ensures clean, precise filling.

Anti-Foam Design: Minimizes bubbles and foam during filling, ideal for viscous liquids like white latex.

Adjustable Filling Speeds: Suitable for low to high viscosity liquids (e.g., coating lubricants, latex).

Safety Features:

Emergency Stop Button: Immediate shutdown in case of emergencies.

Grounding System: Ensures electrical safety in hazardous environments.

Overfill Protection: Prevents containers from being overfilled, reducing waste and spills.

Customizable Options:

Level Sensors: Radar or ultrasonic sensors for precise fill level control.

Capping Machine: Integrated tamper-evident or hermetic capping for sealed containers.

Data Logging: USB or Ethernet connectivity for recording fill data and integration with MES/ERP systems.

Applications:

Coating Lubricants: Filling industrial lubricants, greases, and coating additives.

White Latex: Filling water-based latex solutions used in paints, adhesives, and coatings.

Chemicals: Handling flammable, corrosive, or hazardous liquids in explosion-prone environments.

Pharmaceuticals: Filling solvents, oils, or other pharmaceutical ingredients in hazardous areas.

Benefits:

Safety:

ATEX/IECEx certification ensures compliance with explosion-proof standards.

Static-dissipative materials and grounding prevent sparks in hazardous environments.

Precision:

High-accuracy weighing system (±0.5%) ensures consistent fill volumes, reducing giveaway and waste.

Drip-free nozzles and anti-foam design minimize spillage and contamination.

Efficiency:

Fully automated operation reduces labor costs and increases throughput.

Touch screen interface simplifies setup and reduces training time.

Versatility:

Suitable for a wide range of liquids (low to high viscosity) and container sizes.

Customizable for specific industry requirements (e.g., food-grade, hazardous chemicals).

Hygiene:

Stainless steel construction and CIP compatibility ensure easy cleaning and compliance with hygiene standards.

Tamper-evident capping options prevent contamination.

Cost-Effective:

Reduces product waste, labor costs, and downtime compared to manual operations.

Minimizes cross-contamination risks with dedicated equipment.

Technical Specifications (Example):

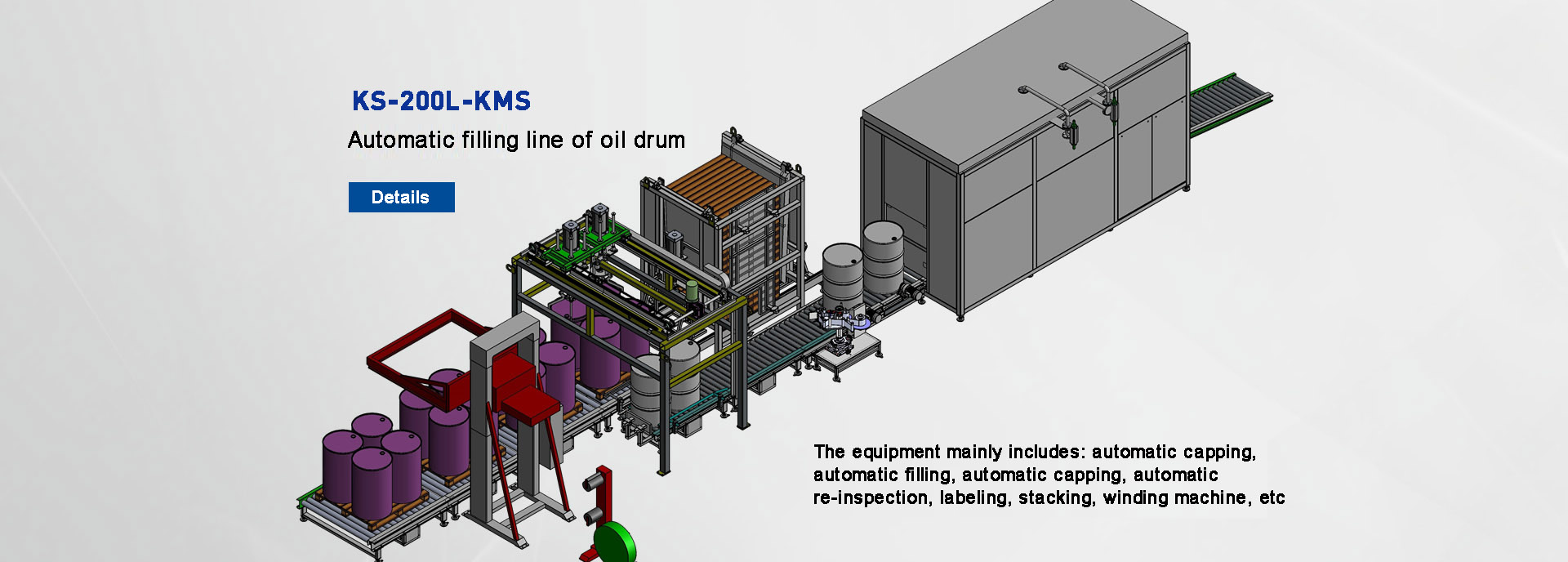

Filling Capacity: Up to 200 liters per minute (adjustable)

Filling Accuracy: ±0.5% (weight-based)

Materials: 304/316L stainless steel (corrosion-resistant)

Power Source: Electric (220V/50Hz or 110V/60Hz) or pneumatic (optional)

Safety Certification: ATEX, IECEx, CE, FDA (depending on configuration)

Dimensions: Compact footprint (e.g., 1200mm x 800mm x 1800mm)

Weight: ~250 kg (depending on configuration)

Touch Screen: Color LCD with user-friendly interface

Optional Add-Ons:

Conveyor System: Automated transport of containers for continuous operation.

RFID/Barcode Scanners: For automatic container recognition and tracking.

Level Sensors: Radar or ultrasonic sensors for precise fill level control.

Capping Machine: Integrated tamper-evident or hermetic capping for sealed containers.

Data Logging: USB or Ethernet connectivity for recording fill data and integration with MES/ERP systems.

Conclusion:

The Weighing Explosion-Proof Filling Machine is a reliable, precise, and safe solution for filling coating lubricants, white latex, and other hazardous liquids in explosion-prone environments. With its advanced features, compliance with safety standards, and customizable options, it minimizes labor costs, ensures accuracy, and enhances safety. Whether you need a basic system or a fully customized solution with advanced features, this equipment is a valuable investment for streamlining liquid filling operations in hazardous environments.

-

1-10L Mulit-Head Weighing Detergent Filling Line[2025-04-29]

-

Cleaner Deodorant Bleach Chemical Liquid Filling Machine for Bottle[2025-06-06]

-

Efficient 200L Liquid Filler with Gear Motor and PLC Control[2025-05-23]

-

Automatic Weighing Double-Station Filling Machine for Filling 1-30L All Kinds of Liquids[2025-04-29]