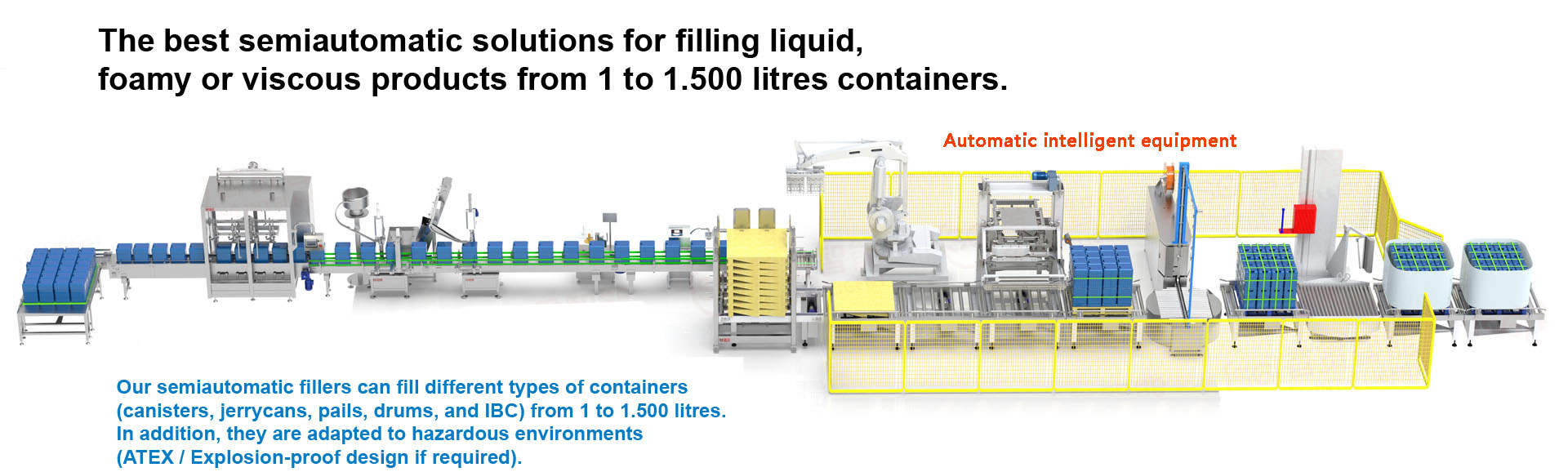

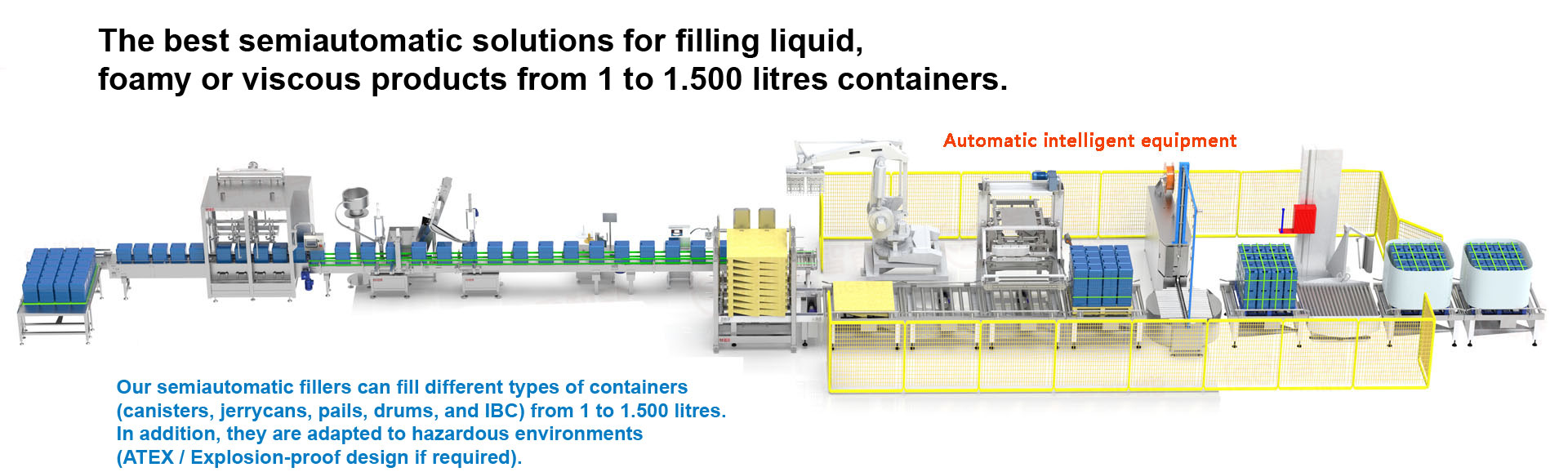

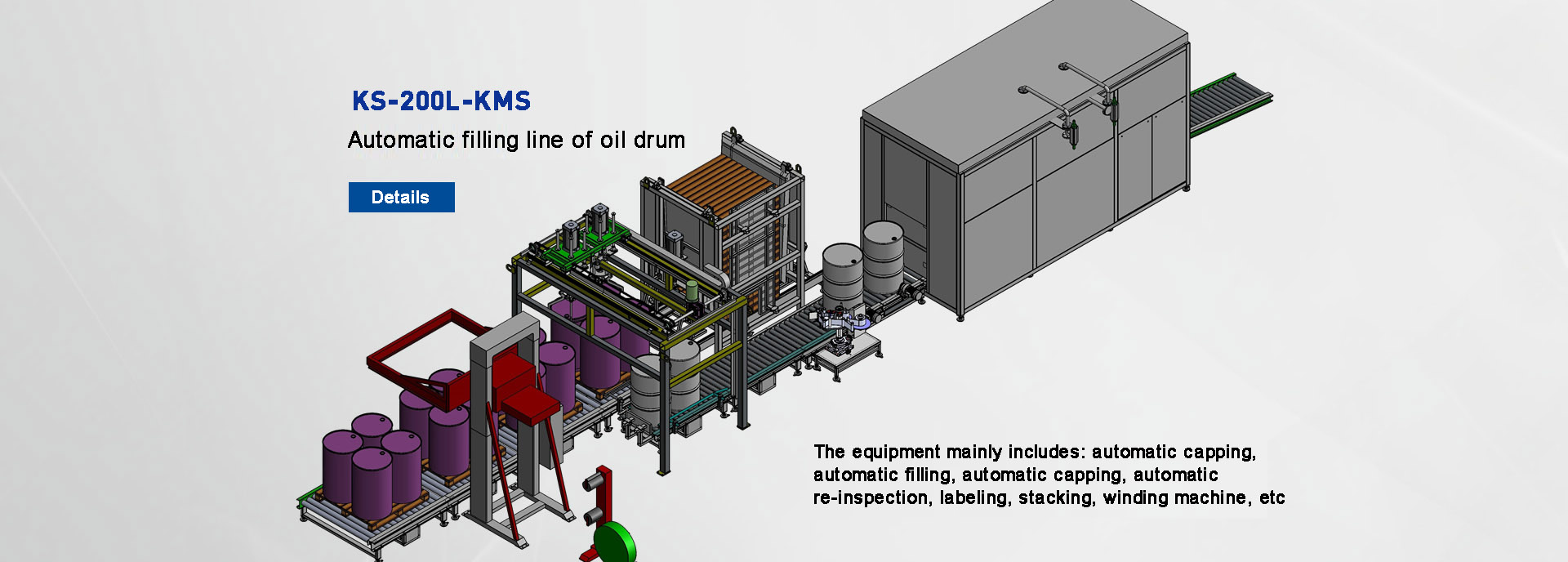

Explosion-Proof Drum Filling Machine

ATEX/IECEx Certified ? ±0.15% Accuracy ? 100% Ignition Risk Elimination

*For Flammable Solvents, Chemicals & Volatile Liquids (Zone 1/21)*

Shanghai Guangzhi Automation’s GZ-ExDrum Series sets the industry benchmark for safe and precise filling of 200L drums with hazardous liquids. Engineered with triple-redundant explosion protection, this ATEX/IECEx-compliant system eradicates ignition sources, captures 99.9% VOC emissions, and delivers ROI in <12 months through zero material loss and labor reduction.

Core Safety Technologies

? Pressurized Control Cabinets

Ex pxb IIC T4/T6 rated – maintains positive pressure to exclude explosive gases.

? Intrinsically Safe Sensors

Ex ia IIC T6 circuits (<1mA energy) for level, flow, and vapor detection.

? Static Dissipation System

Conductive fill lances (10? Ω) + auto-grounding verification (<10 Ω resistance).

? Double-Sealed Motors

Ex db IIB+H2 T4 rated pumps with leak detection.

? Emergency Inerting

Nitrogen purge activates if O? >5% or VOC >25% LEL.

Technical Specifications

Table: GZ-ExDrum Performance & Safety Metrics

| Parameter | Specification | Certification |

|---|

| Filling Volume | 20–220 L (adjustable) | – |

| Accuracy | ±0.15% (gravimetric) | OIML R117 Class 0.5 |

| Throughput | 50 drums/hour (200L) | – |

| Viscosity Range | 1–150,000 cP | Heated path (150°C) optional |

| Explosion Proof Rating | ATEX: Ex db eb ib mb IIC T4 Gb | IECEx: Ex db eb ib mb IIC T4 Gb |

| Material Contact | Hastelloy C-22 / PFA / Kalrez? 6375 | NACE MR0175 (H?S service) |

| Power Supply | 480V/60Hz, 8.5 kW (isolated transformer) | IP66 enclosure |

| Control System | Remote 12" HMI (Zone 2) + Fiber-Optic PLC | SIL 3 (IEC 61508) |

| Safety Systems | VOC/O? sensors, seismic shutdown, flame arrestors | API 2350 |

| Compliance | PED 2014/68/EU, ASME B31.3 | UKCA, EAC TR CU 012 |

Industry-Specific Protection